Pipe coating process

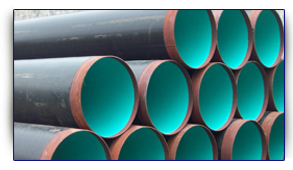

for the corrosion protection of pipeline many types of coating and wrapping are applied.

for the corrosion protection of pipeline many types of coating and wrapping are applied.

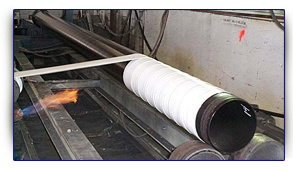

Before the blast cleaning process, we protect all pipe ends with end caps as standard. Pipe preparation is a key factor in the application of coatings therefore we pay particular attention to the cleaning process to achieve the highest standard possible. The process includes two external blast cabinets, the first of which uses steel shot followed by steel grit in the second machine. We select the most appropriate grades of abrasive and control parameters to ensure optimum results.

Our people utilise expertise and experience derived from the steel, coatings and hydrocarbons industries. They understand the criticality of coated linepipe performance. Our commitment to delivering world-class coated linepipe is reflected in the fact that our team holds third party approvals and accreditations. To maintain skills and keep abreast of coating technology, we invest in an ongoing training programme both in house and externally.

Specifiaction

| External Coating | • 3LPE/PP • FBE (Mono&Dual Layers) • CTE • Mortar Lining • Gunnating |

| Internal Coating | • Internal Epoxy • Flow Coat • Cement Lining |

| Capacity | External : 450 sqmtr/hr Internal : 350 sqmtr/hr |

Product Range:

| Types of Coating | Capacity |

| 3 LAYER POLYETHYLENE / POLYPROPYLENE FBE coating | External : 450 sqmtr/hr Size range : 6” to 64” OD |

| INTERNAL EPOXY coating | Internal : 350 sqmtr/hr Size range : 6” to 64” OD |

External Coating Solutions

External Three Layer Polyethylene / Polypropylene [3LPE / 3LPP] Coating:

Citizen Metals 3LPE / 3LPP Coating is a multilayer coating composed of three functional components. This coating consists of first layer which is a high performance anti-corrosion fusion bonded epoxy [FBE] second layer of a copolymer adhesive for adhesion between the epoxy and PE / PP and an outer / third layer of polyethylene / polypropylene which provides mechanical protection.

3LPE Coatings provide excellent pipeline protection for small and large diameter pipelines with moderate to high operating temperatures whereas 3LPP Coatings not only provides the toughest, and the most durable pipe coating solution but also provide excellent pipeline protection for small and large diameter pipelines with high operating temperatures.

Single Layer / Dual Layer Fusion Bonded Epoxy [SFBE / DFBE] Coating:Citizen Metals SFBE is single layer anti-corrosion coating which consists of high performance fusion bonded epoxy that provides excellent adhesion to steel and provides superior long term corrosion resistance protection of pipelines operating at moderate temperatures for the designed life.

Excellent adhesion properties provide excellent resistance to cathodic dis-bondment which reduces the total cost of cathodic protection during the operation of the pipeline. DFBE is a layer of anti-corrosion coating followed by abrasion resistant overcoat which provides excellent results for pipe being used in abrasive conditions.

Product Range:

|

TYPE |

DIAMETER RANGE |

SPECIFICATION¹ |

||

|

External Three Layer Polyethylene / Polypropylene [3LPE / 3LPP] Coating |

4” [114.3 MM] |

As per DIN |

||

|

Single Layer / Dual Layer Fusion Bonded Epoxy [SFBE / DFBE] |

4” [114.3 MM] |

As per CSA |

||

|

Note: |

1 |

Pipes can be supplied as per Customer Specification also. | ||

Application Industry:

- Oil & Gas Pipelines

- Water Pipelines

Internal Coating Solutions

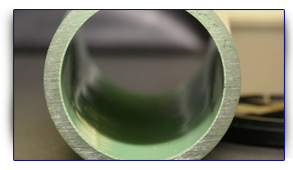

Internal Liquid Epoxy: Citizen Metals internal liquid coating plant is designed to apply a suitable spray coating on the inside surface of pipes for transportation of oil, gas, water & any types of liquids. Liquid Epoxy coating is applied on abrasively cleaned internal surface of pipe with the coating thickness minimum 60 µm & Maximum up to 2000 µm with single or multi coat as required.

Citizen Metals internal liquid coating plant is designed to apply a suitable spray coating on the inside surface of pipes for transportation of oil, gas, water & any types of liquids. Liquid Epoxy coating is applied on abrasively cleaned internal surface of pipe with the coating thickness minimum 60 µm & Maximum up to 2000 µm with single or multi coat as required.

Coating can be applied by using Liquid Epoxy (single or dual component), having characteristic with solvent base or solvent free epoxy which is applied to give smooth internal pipe surface for improved flow and also to provide corrosion protection for the internal surface of steel pipes. This will result in reduction of friction and increase in flow efficiency.

Application Industry:

- Oil & Gas Pipelines

- Water Pipelines

Internal Cement Mortar Lining:

Internal Cement Mortar Lining plant is designed to apply a suitable Cement Mortar Lining on the internal pipe surface, per AWWA coating specifications. Typically used for transportation of water or sewage.

Internal cement mortar lining is performed by use of a spinning machine, which rotates the pipe causing the cement mortar to adhere centrifugally to form uniform, smooth, and dense protective lining. Once completed, water is sprayed and ends are capped as per the curing procedure and customer specification for guaranteed strength and protection.